Crushing and the Importance of Conveyor Safety

consistently leads the industry in new product innovations. We stand by our products with unsurpassed service and support to make your job easier. Get serious. Get Eagle Crusher. • Durability and longevity. • 24-hour parts and service. • American made. • Highest productivity and profits. • High resale value.

Learn MoreSafety Consideration in the Development of Improved Stone

Abstract - There is need for safer design and development of stone jaw crusher taking with due consideration of the necessary safety and required

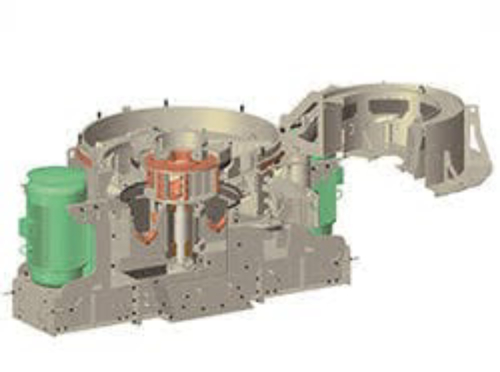

Learn MoreGyratory Crusher - an overview | ScienceDirect Topics

However, the gyratory crusher is sensitive to jamming if it is fed with a sticky or moist product loaded with fines. This inconvenience is less sensitive with a single-effect jaw crusher because mutual sliding of grinding surfaces promotes the release of a product that adheres to surfaces. –

Learn MoreSafe operation and use of mobile jaw crushers - HSE

The crusher should be shut off and isolated before considering the use of bars and hand hammers. Careful consideration should be given to the

Learn MoreBall Crusher Toy Safety - Body Jewelry & Piercing Blog | The Chain

8/17 · In order for a ball crusher to be safe it needs to have a proper design that is made for pain and pleasure but that also ensures safety. Also, it is vital that people use this toy with caution. Ball crushers are specially designed to provide very

Learn MoreKleemann Crusher Safety Manual - Automotive Repair Manual-Heavvy

Kleemann Crusher Safety Manual Size : 3.25 MB Format : PDF Language : English Brand: Kleemann Type of machine: Crusher Type of document: Safety Manual Model: Kleemann Crusher Safety Number of Pages: 53 Pages Order Number: SIH_0099_F20008844_C _en-GB

Learn MoreCrusher Safety | Crusher Mills, Cone Crusher, Jaw Crushers

CRUSHER SAFETY PRECAUTIONS -Ball Mill BEFORE OPERATION. Maintain a metal-to-metal contact between container and fuel tank when filling the tank. Use particular care when handling batteries and electrolyte. Jaw crusher complete safety operation - bauxite crusher

Learn MoreCrushers - an overview | ScienceDirect Topics

Rotary bottom crusher. The main manufacturing steps are as follows: • Site selection and separation • Weighting and control • Fragmentation • Primary crushing • Steel separation by magnetic means • Manual separation of plastic, wood, and paper • Secondary crushing • Sieving View chapter Purchase book

Learn MoreThe Importance of Hopper Feeder Safety When Crushing

This article does not serve as an official safety recommendation by and should not be viewed as such. All relevant staff should

Learn MoreHealth and Safety in Stone Crushing

SAFETY & HEALTH. IN THE. STONE CRUSHING. INDUSTRY. A Practical Manual for Preventing Accidents,. Preserving Health and Keeping a Company Profitable.

Learn MoreCrusher Safety Tooling - ME Elecmetal

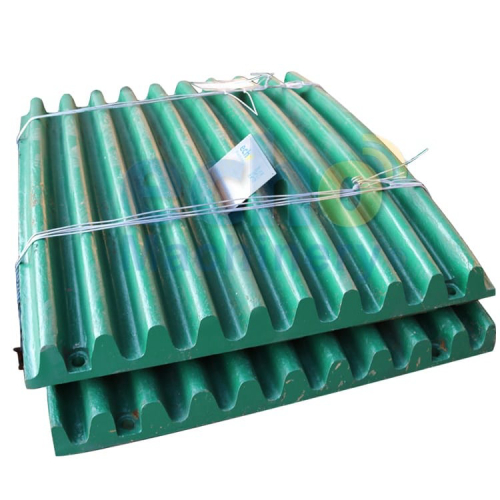

Crusher Safety Tooling ME Elecmetal is your source for crusher safety products in North America. We offer: Primary corrals Dump pans Setting fixtures Crusher nuts Power shackles Spider hooks and more Contact your account manager or request a quote for more product information.

Learn MoreCrusher safety goggles - Lawn & Landscape

Safety Gear Whether working in the elements or working up a sweat, Brass Knuckle Crusher (BKDST-1020NP) safety goggles have specialized channels along the brow line to move water and sweat away from the eyes, while the rubber gasket seals glasses snugly against the face. The gasket does double-duty as anti-dust protection, too.

Learn Morecrusher plant safety inspection findings

Feb 16, · Safety on a crusher starts with the person feeding the plant. The person feeding the plant needs to be trained on best practices specific to the crusher they are working with. An operator may have years of experience operating and loading a cone crusher, but that doesn't translate into experience loading and operating a jaw crusher.

Learn More6 ways to improve crushing safety - Outotec

6 ways to improve crushing safety · Report unsafe practices or conditions · Don't rush work to meet deadlines · Prioritize education about programs and procedures.

Learn MoreCone Crusher Safety And Maintenance | Crusher Mills, Cone Crusher, Jaw

Cone Crusher, Ores and Rocks Crusher for sale -Ball Mill. cone crusher series easy maintenance, convenient chamber so as not to damage the cone crusher. The safety system uses dry oil and water as two

Learn More7 Crusher Equipment Safety Tips - Multico Prime Power Inc. Philippines

These crusher safety tips will prevent accidents in the workplace, maintain functioning equipment for a long time, and increase productivity. The key here is to prioritize training your operators so they know how to wear protective clothing, work within a crusher's capacity, maintain it, and keep the area clean.

Learn Moresafety operation of crusher

safety operation of crusher Crusher Wikipedia. A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust. . Mining operations use crushers, commonly classified by the degree to which they fragment the starting material, with . The safety cylinder of the machine can ensure safety as

Learn MoreCrusher inspections - Outotec

More thorough and specialized inspections should then be conducted by Outotec experts. 1000-hour Operating Inspection: up to two hours with the equipment operating and about 4-6 hours shutdown depending on whether it's a stationary or mobile operation to review general condition of equipment. This includes a review of key wear

Learn More7 Crusher Equipment Safety Tips - Multico Prime Power Inc

What are the crusher equipment safety tips? Train operators about crusher safety; Keep instruction manuals nearby; Wear PPE at all times

Learn MoreImproving jaw crusher safety | WEG

7/15 · /07/15 According to the Health and Safety Executive’s guidance for the safe operation and use of mobile jaw crushers, equipment operators may be subject to

Learn MoreNew Brass Knuckle® Orange Crush Safety Goggles

New Brass Knuckle® Crusher Safety Goggles Channel Water Away. Tuesday, November 22, 2016. Groove-and-gasket combo keeps vision clear for safe,

Learn MoreAMIT 129: Lesson 12 Crusher and Mill Operation Safety

Maintenance procedures must take account of manufacturer's instructions and safety warnings. When performing maintenance inside large jaw crushers a

Learn MoreSafe and sound: Crusher safety : Pit & Quarry

7/14 · These have surely eliminated some accidents and enhanced worker safety. Still, a crusher accident can happen in a moment’s notice. When a worker makes a poor decision.

Learn MoreCrush Warning Labels- ANSI Safety Crush Hazard Labels

Crushing Hazard Labels Crush Warning Labels - UL® Recognized Order crush warning labels that are UL® Recognized, meeting requirements for heat resistance, chemical resistance, and other attributes.

Learn MoreJual Safety Crusher Terlengkap - Harga Terbaru ... - Tokopedia

Beli Peralatan Safety Crusher Online berkualitas harga murah September 2022 di Tokopedia! ∙ Promo Pengguna Baru ∙ Kurir Instan ∙ Bebas Ongkir ∙ Cicilan

Learn MoreEnhancing safety around crushers - Pit & Quarry

Additionally, keep your crusher working safely and efficiently by performing regular maintenance inspections. This allows you to pinpoint

Learn MoreJual Sepatu Safety Crusher Terbaik - Tokopedia

Beli Sepatu Safety Crusher terbaik harga murah September 2022 terbaru di Tokopedia! ∙ Promo Pengguna Baru ∙ Kurir Instan ∙ Bebas Ongkir ∙ Cicilan 0%.

Learn MoreNew crusher improves quarry efficiency and operator safety

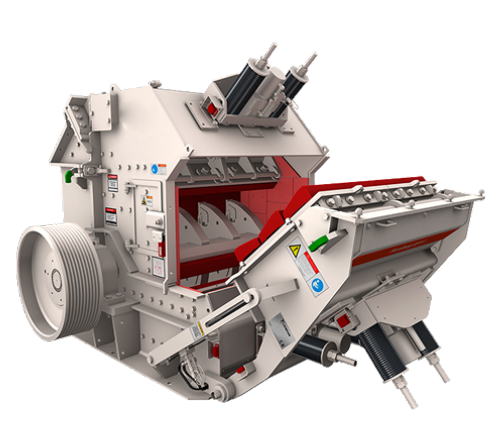

12/13 · New crusher improves quarry efficiency and operator safety. QI353 impact crusher has been built with more productivity, connectivity and safety at the forefront of its innovative design. has launched a new crusher, QI353, which is the most versatile, mid-sized mobile impact crusher available on the market.

Learn MoreSite Safety and Safer Aggregate Crushing Operations - Agg-Net

This will allow them to pinpoint any problems that may make the machine unsafe to use. Tips for keeping a safe crusher include operating the crusher at its

Learn MorePDF Sand, Gravel, and Crushed Stone On-the-job Training ModulesPDF

by a secondary crusher, and sometimes a tertiary crusher. Raw material, of various sizes, is brought to the primary crusher by rear-dump haul units, or carried by a w heel front- end l oader . Pr imar y cr ushi ng reduces thi s run- of -mine r ock to a more manageable size. The different types of primary crushers are: jaw crushers, gyratory

Learn MoreAre Your Workers in Danger of Crushing Injuries?

Strategies for controlling crushing hazards include: Guarding. Ensuring that machinery is properly guarded will prevent many crushing injuries, deaths, and amputations. Prohibit workers from removing guards while machinery is in use. Make sure that guards don't create an additional hazard.

Learn More

Leave A Reply