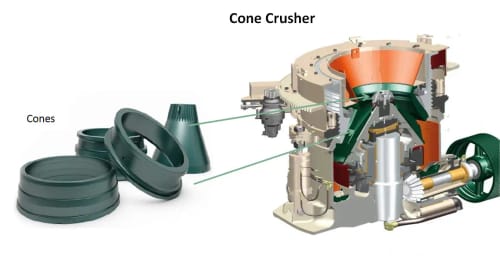

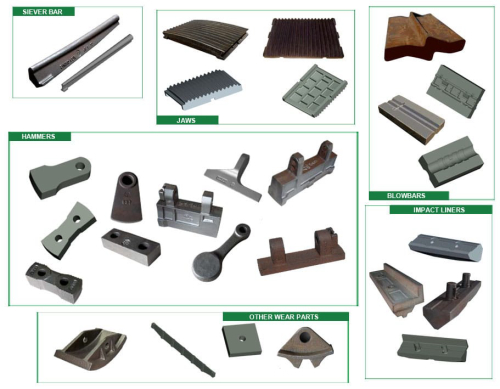

Cone Crusher Liners For Popular Brands With Various Material

Through our application-driven, site-specific engineering capabilities, our offering of replacement cone crusher parts of most any origin has gained acceptance

Learn MoreWhen do you change cone liners? - ELRUS

Oct 06, · Posted by ELRUS Aggregate Systems on Mon,Oct 06, @ 08:10 AM. There is an optimum time to change your cone liners. Too soon and you don’t get the value for the cost of

Learn MoreREAL-TIME OPTIMIZATION OF CONE CRUSHERS - CORE

The wear of crusher mantle liners and screen cloths dramatically affects the products and the performance of the crushing process, Svedensten [46]. Changing.

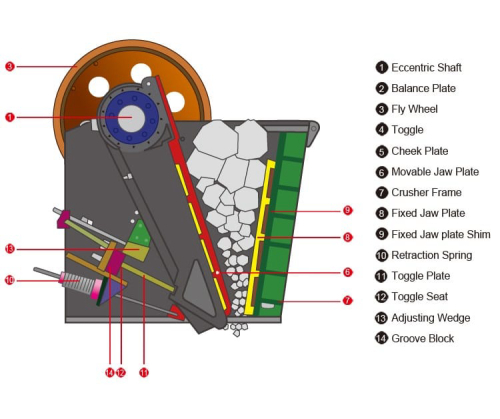

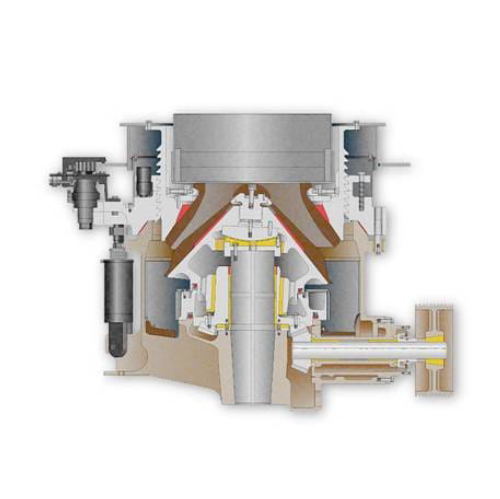

Learn Morecone crusher liner change simons crusher cone 5 1 2 bottom shell

Liner change Dismantling of crusher Technologically unique, the new generation cone crushers offer unprecedented performance. Their safe and easy maintenance ensure maximum reliability. 5 19 - Antispin device 20 - Head 21 - Upper head bushing 22 - Mantle 23 - Hydraulic adjustment motor 24 - Bowl liner 25 - Bowl liner fixation

Learn MoreResearch on the Wear Behavior of the Fixed Cone Liner of a

In the working process of a cone crusher, the cone crusher constantly impacts the ore with the change of the distance between the moving cone

Learn MoreProlonging Cone Crusher Liners Working Life - Precision Casting

This occurs when the stone being crushed is forced against the liner causing it to ‘work-harden’. ‘Green’ manganese starts off at around 25 Rockwell (250 Brinell) and can

Learn MoreCone Crusher Liners - Makuri Group

Cone Crusher Liners Makuri provides real solutions for cone crusher liners that go above and beyond the usual OEM standard profiles, leading to measurable improvements and lowest TCO every time. Unplanned shutdowns to change mainframe liners and arm guards —life doesn’t match main liners;

Learn MoreCone Crusher Wear Parts - Unicast Inc

Durable cone crusher wear parts - bowls and mantles, liners, torch rings, We offer high quality replacement wear parts for cone crushers,

Learn Morehow to prolong cone crusher replacement working life?

This post explains a method to reduce crusher replacement costs by casting crusher liners. However, the process has been perfected in recent

Learn MoreCone crusher basics in 4 minutes — SRP

Cone crusher basics in 4 minutes. This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more

Learn MoreLiner change solves heat issue; improves production and

its cone crusher led a copper mine to contact FLSmidth. A new liner profile solved the challenge and improved the site’s overall performance. WE DISCOVER POTENTIAL Results at a glance 30% increase in production Liner life doubled 32% increase in availability 18% reduction in heat generation M 05-19 0000-9-ENG Liner change solves

Learn MoreCrusher Liners | Cone Crusher Liners | Crushing Wear Parts

Made to fit, reduced downtime and ease of replacement - Precise fitting for less wear and te equipment and for quick and easy replacement. Increased crusher uptime - Replacement and Custom Design and Proprietary alloys offer proven increased crusher efficiency, prevent premature erosion, and extend usable wear life.

Learn MoreRead now 9+ cone crusher liner most prestigious - Công lý & Pháp

1.Cone Crusher Liners: How to Select and When to Change; 2.World-Leading Crusher Liners – CMS Cepcor; 3.Cone Crusher Liners | Crushing Wear Parts – Cast Steel Products; 4.Cone Crusher Wear Parts – Columbia Steel Casting Co., Inc. 5.Replacing the liner of a HP cone crusher – Outotec; 6.Yong Won SP300 Super Cone Crusher liner

Learn MoreLiner change solves heat issue; improves production

its cone crusher led a copper mine to contact FLSmidth. A new liner profile solved the challenge and improved the site’s overall performance. WE DISCOVER POTENTIAL Results at a glance

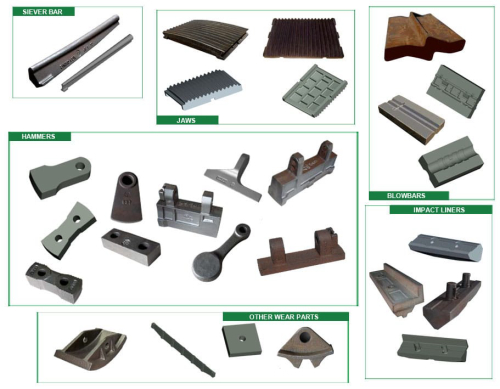

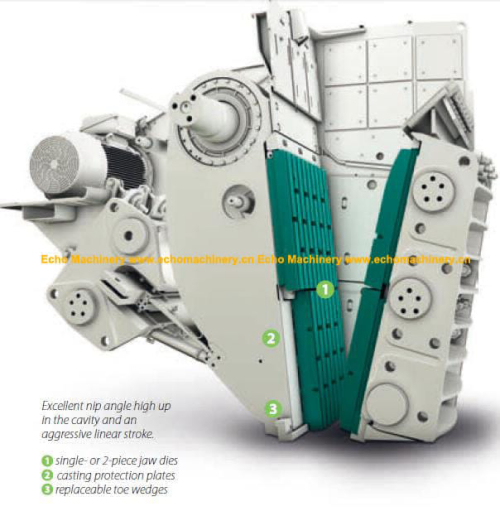

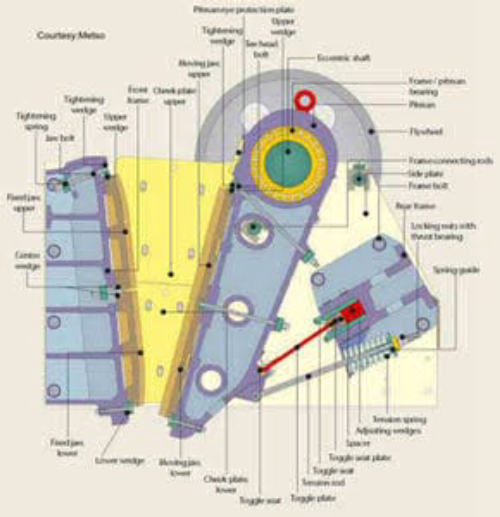

Learn MoreLiner wear in jaw crushers

Wear in rock crushers causes great costs in the mining and aggregates industry. Change of the geometry of the crusher liners is a major reason for these

Learn Morecone crusher liner change | stone crusher bushing usa

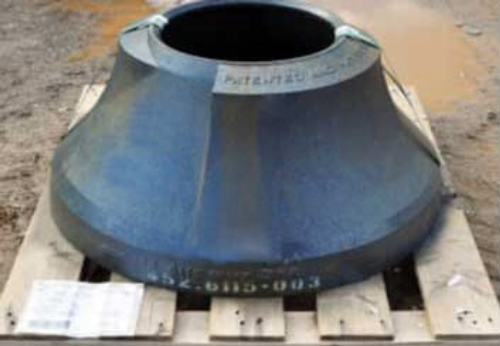

Cone crusher liner plate (concave and mantle) have many functions: improve grinding media, grinding ore, protection of grinding cylinder. Change Cone Crusher Liners Next Next post: SAG Mill Liner Types. Related posts. Manganese steel casting foundry 08/08/2020. Ball Mill Liners Material Selection And Application 09/07/2020.

Learn MoreChange Cone Crusher Wear Parts - Precision Casting

There are two situations need to change cone crusher wear parts: Situation 1:Normal Abrasion. In order to avoid damage to the liner seating surfaces of the crusher head or bowl, wear parts must be replaced before they are worn through. In normal conditions, approximately 50% of the liner weight is consumed when liners are worn out.

Learn Morecone crusher liner change | high quality cone crusher wear copper

Change CSS. Replace the cone crusher liner. Tags: Common faults Cone crusher Solutions. Written by Rayco. 20 years of experience in the mining and construction aggregate industry, to provide advice on your mining or quarry projects. Leave a Comment Cancel. Your email address will not be published.

Learn MoreStone Crusher wearliner change

Mar 04, · Mantle swap operation. Displaying the problem of todays technique to lift off the mantle from the shaft. It is done by welding two metal plates with holes in

Learn MoreCone Liners / Concaves / Mantles for Finlay C - Samscreen

Cones/ Cone Liners / Concaves / Mantles for Finlay C- 1540 Cone Crusher. At Samscreen, we're pleased to provide replacement crushing products for numerous

Learn MoreCone Crusher Liners: How To Select And When To Change - Weebly

Feed is the primary component of Cone Mill Liners Foundry. A well-graded feed should be utilized to crush the material. A feed that is graded properly should include: 90-100% passing the closed-side feed opening. Some people also look at the open side, and then choose the smaller one. 40%-60% at the middle 0-10% passing the closed-side setting.

Learn MoreLiner Replacement For Cone Crusher - How simple it is!

Leading Crushing and Screening Equipments Manufacturer in Korea.

Learn Morecone crusher liner change | LT110 CAP SCRW HEXSCKTHD ISO4762-M5X130-12.9

How to change cone crusher liners? Normally, there are 6 steps to change cone crusher liners: On the first collection of brand-new linings, position a mark on the modification cap chauffeur ring where the pinion tooth reaches a motorist ring tooth when the target crusher setting has actually been accomplished.

Learn MoreCone Crushers | McLanahan

When should I replace my Cone Crusher liner? If the liner is wearing evenly throughout the chamber, you should consider changing out the manganese when it has worn down to about 1" (2.5 cm) thick at the bottom. At about 3/4" to 5/8" (1.9 to 1.6 cm) thick, the manganese will crack, causing the backing material to begin to disintegrate.

Learn MoreHow To Select Cone Crusher Liners and When To Change

The Cone Crusher liner should have a well-graded feed flowing into the crushing chamber. This generally consists of: 90 to 100 percent passing

Learn MoreChina Cone Crusher Liner Change Manufacturers and Suppliers - Factory

Cone Crusher Liner Change - Manufacturers, Suppliers, Factory from China Our target is to consolidate and improve the quality and service of existing products, meanwhile constantly develop new products to meet different customers' demands for Cone Crusher Liner Change, H8800 Cone Crusher Wear Parts , Nerdberg Cone Crusher Spare Parts , 3

Learn MoreHP800 CRUSHER OPTIMIZATION - H-E Parts

competitor supplied crusher liners, across all three cone crushers. ™ lifting device when liner change-outs are required.

Learn MoreHow To Select Cone Crusher Liners and When To Change Them

Dec 27, · How To Choose. 90 to 100 percent passing the closed-side feed opening. 40 to 60 percent going through the midpoint. 0 to 10 percent leaving the closed-side setting.

Learn MoreFailure to adequately maintain crushers comes at a high price

As cone crusher liners wear, the operator threads the bowl inwards, price of the liner change you should consider changing the liners.

Learn MoreResearch on the Wear Behavior of the Fixed Cone Liner of a Cone Crusher

May 05, · Taking reducing the wear of the fixed cone liner of a cone crusher as the starting point, the movement and geometry parameters of the cone crusher are studied using the discrete element method. but the change trend is different. The effect of the dynamic friction coefficient on the repose angle is obviously greater than that of the static

Learn MoreWhen & How To Change Cone Crusher Liners? - Hunan JY Casting

Replace the cone crusher concave Blow liner removal Remove the bowl liners as follows: Remove the adjustment cap and the bowl earlier. Thoroughly clean the threads on the adjustment ring, clamping ring, and bowl, removing all traces of dirt, rust, and old grease. Lift the feed hopper from within the bowl.

Learn More

Leave A Reply