Beaverton, OR - Crushers For Sale - Equipment Trader

The three main types of crushers are the cone crusher, the jaw crusher, and the impact crusher. Make sure you understand all of the differences between these kinds before choosing one for your project. Regardless of which type of machine you choose, you should be prepared for some very powerful crushing power.

Learn MoreImpact Crusher Design | Crusher Mills, Cone Crusher, Jaw Crushers

Cone crusher Cone crusher design. Cone crusher is mainly used in secondary or tertiary stone crushing process. is a Cone crusher manufacturers owns a more , Impact Crushers,Fine Crushers,Impact Crushing,Primary Impact ,

Learn MoreCone Crusher | Working Principle | Animation | Engineering Intro

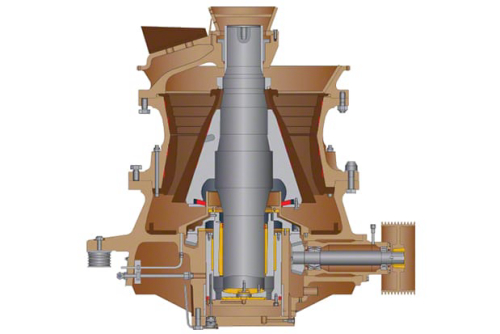

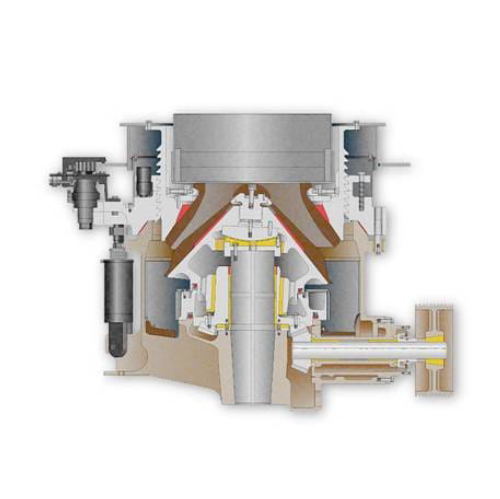

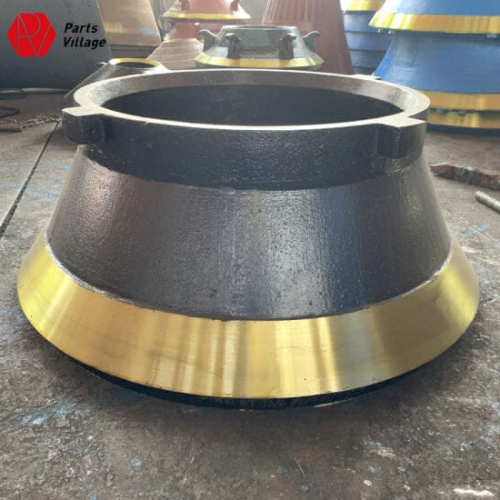

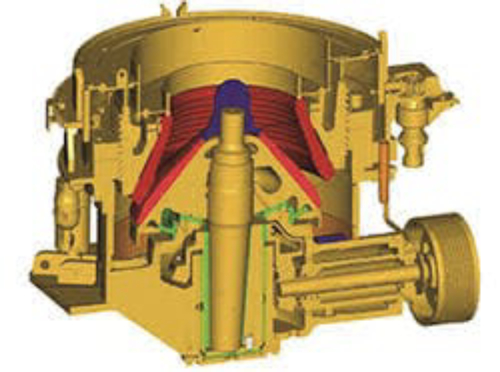

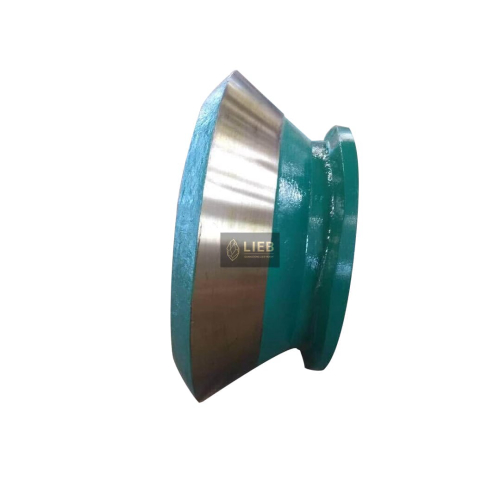

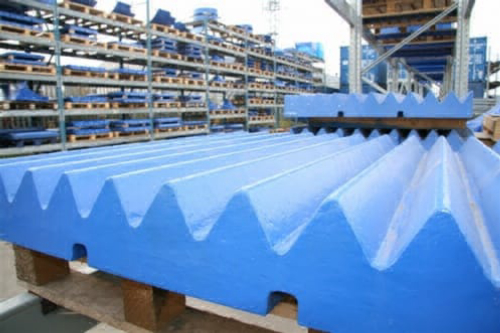

Cone crusher has a less steep crushing chamber and more parallel zone between crushing zones. It breaks the rocks by squeezing it between the gyrating spindles. These spindles are fully covered with resistant mantle and a manganese bowl liner covers the hopper. Rocks get squeezed at the same moment when it enters in between the bowl liner and

Learn More12 tips to maximize cone crusher productivity

There are a few design limitations in each cone crusher: the volumetric limit, the horsepower limit and the crushing force limit.

Learn MoreHammer Crusher Design PDF | Crusher Mills, Cone Crusher, Jaw Crushers

HP series Cone Crusher adopts computer optimization design to speed up main shaft speed. design of hammer coal crusher, hammer mill free construction drawings and design pdf- [crusher , Hammer Mill Design,spice grinder,pulverizer,grinding coal crushing ball mill design; maintenance hammer crusher manual India - Mineral

Learn MoreCone Crusher Manufacturer | Propel Industries

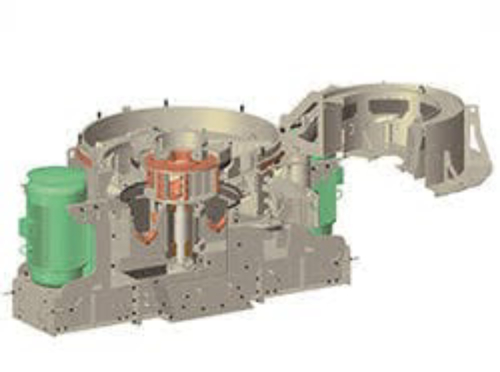

Propel QM series Cone Crushers combine the best power utilization per cone diameter, cavity design of higher density, optimized crusher speed and efficient throw. The higher cavity density improves the inter-particle Read More, GYRATORY CONE CRUSHER, The Gyratory Cone Crusher delivers increased capacity with reduced maintenance and downtime.

Learn MoreThe pros and cons of cone crusher applications - Quarry

Cone crushers can be categorised into three main design types. With floating bowl and screw bowl cone crushers the upper frame raises to open CSS or relieve crushing pressure. The third type - the spider-bearing cone crushers - incorporate a shaft supported by a hydraulic piston which controls CSS and crushing pressure.

Learn MoreRaptor® Cone Crushers for Aggregates

Raptor® Cone Crusher — your needs guide our design You need safety, ease of maintenance and the highest possible throughput. Our Raptor Cone Crushers have all that and more. We created our aggregate line of cone crushers working with customers like you. These crushers are smaller than those we recommend for mining applications, but they

Learn MoreCone crushers - for demanding crushing needs - Outotec

Cone crushers are equipped with a hydraulic setting adjustment system, which allows adjusting the crusher settings to fully match the material, feed size, and capacity requirements. Our cone crusher offering consists of four different product families that utilize the same crushing principle but vary in features and optimal applications.

Learn MoreChamber Optimization for Comprehensive Improvement of

Furthermore, taking the existing C900 cone crusher as the research object, and the rotating speed are determined as the design variables of the

Learn MoreCone Crushers - Astec

Cone crushers reduce material by compression, sizing material according to the gap setting. Intended for mining, construction aggregates, industrial and recycling applications, the durable Astec cone crusher lines are manufactured in various sizes, configurations and capacities to meet the demands of the competitive market. Crushing.

Learn MoreKubria® cone crushers

Whether a standard or special design thyssenkrupp. Industrial Solutions can provide the optimum solution to meet your needs. Our flexibility is a major plus: We.

Learn MoreHigh-Efficiency Cone Crusher ZI Cone Crusher | ANSWERS

is highly reputed for its customized crushing chamber design and for developing mining and minerals processing solutions.

Learn MoreCone Crusher Design - Metallurgist & Mineral Processing Engineer

14/02/ · Design Features The 2390 Omnicone has the following advanced design features for ease of operation and maintenance and increased productivity. Cavity clearing for reduced

Learn Moredesign for iron ore

how can i design an iron ore crusher. iron ore crusher design applications palashresidency Jaw Crusher, Cone Crusher, Vertical Shaft Impactor In Iran Conmix Crusher is the best in manufacturer and supplier of Jaw Crusher, Cone Crusher is simplicity of design and rugged construction has made for It can be used to crush both hard and medium hard materials, such as limestone .

Learn MoreQM Series Cone Crushers | Propel Industries

CONE CRUSHER QM SERIES . Propel QM series Cone Crushers combine the best power utilization per cone diameter, cavity design of higher density, optimized crusher speed and efficient throw. The higher cavity density improves the inter-particle crushing action.

Learn MorePDF) Cone Crusher Performance - ResearchGate

13/05/ · In this thesis a method for prediction of cone crusher performance is presented. The model is based on the laws of mechanics and constitutive relations concerning rock breakage

Learn MoreCrusher Aggregate Equipment For Sale in BEAVERTON, OREGON - 29 Listings

Browse a wide selection of new and used Crusher Aggregate Equipment for sale near you at MachineryTrader.com. Find Crusher Aggregate Equipment from KPI-JCI, CEDARAPIDS, and , and more, for sale in BEAVERTON, OREGON

Learn MoreCone Crusher Design - China Manufacturers, Factory, Suppliers

Cone Crusher Design Well-run products, skilled income group, and better after-sales products and services; We have been also a unified massive family, all people stick with the business price "unification, dedication, tolerance" for Cone Crusher Design, Impact Crusher Settings , Sj1380 Cone Crusher Spare Parts , Impact Crusher Of 1315 , Gp11f

Learn MoreCone Crusher - an overview | ScienceDirect Topics

The secondary crushers are designated as Standard cone crushers having stepped liners and tertiary Short Head cone crushers, which have smoother crushing faces and steeper cone

Learn More12 tips to maximize cone crusher productivity

11/02/ · Cone crusher productivity can be easily increased by a minimum of 10 % by having better feed control. It can be achieved by using surge piles, hoppers and variable speed feeding

Learn MoreCrushing and Screening Handbook - AusIMM

preparation, structural design, and supply and Jaw crushers are mainly used as primary crush- Due to their design, cone crushers are gener-.

Learn MoreCrushing technology - kleemann

Jaw crushers, cone crushers and impact crushers with a high throughput Due to their design, cone and gyratory crushers are limited with regard to the

Learn MoreDESIGN AND ANALYSIS OF IMPACT CRUSHERS - National

DESIGN PARAMETERS: The principal design parameters that drive crushing plant selection and configuration included. 1. Production Requirements 2. Ore characteristics 3. Project location 4. Operational considerations 5. Climate conditions 6. Capital cast 7. Safety & environment 8. Life of mine plants. 9. Maintenance requirements. Fig.1 Fig.2

Learn MoreCone Crushers - Sandrock Mining

Cone crushers are a type of compression crusher used by aggregate, coal, concrete, crushing, fracking sand, and mining industries, which reduces material by squeezing or compressing it until it breaks. increase the life of crusher and reduce maintain cost.Optimal design of the hydraulic station and other parts make the operation and

Learn MoreCone Crushers | Moore Watson Ltd

The MP Cone Crusher is advanced in design, more compact with a higher crushing ability and efficiency to provide better size reduction. Operators can choose the auto control mode, various chambers and other features by adjusting the closed side settings (CSS). All models are easy to operate and maintain, with high production and efficiency.

Learn MoreCone Crushers | Crushing Plants | DOVE

Capacities are based on continuous regulated feed of clean, dry limestone of normal hardness with a bulk density of 16 ton/m3. Capacity may vary with the size and nature of the rock and the working conditions of the plant. DOVE reserves the right to modify the specifications at anytime, without prior notice.

Learn MoreCone Crusher Design

09/10/ · Cone Crusher Design Tuesday, October 9, SBM - Marble crusher manufacturers available now Conveyors and Crushing Equipment's production units offer state

Learn Morecone crusher design and operation

cone crusher design and operation Cone Crusher Design And Operation foremostmarbles.co.in cone crusher design and operation cone crushers Operation Principle Of Cone

Learn MoreCone crusher basics in 4 minutes — SRP

Cone crusher basics in 4 minutes This is the starting point for understanding how cone crushers work – and how they can make your mine or quarry more productive. Elsewhere on the site you

Learn MoreCone Rock Crusher Design | Crusher Mills, Cone Crusher, Jaw Crushers

Cone Crusher and ore crushers in uae.CS cone crusher,stone crushing of many kinds of mining and rock, series stone crushing equipment’s design cone crusher design the best this is product template is a complete ore processing plant manufacturer in China, supplies all kinds of best ore mining and crushing machines for

Learn More

Leave A Reply