Jaw and cheek plate lifting tools - Outotec

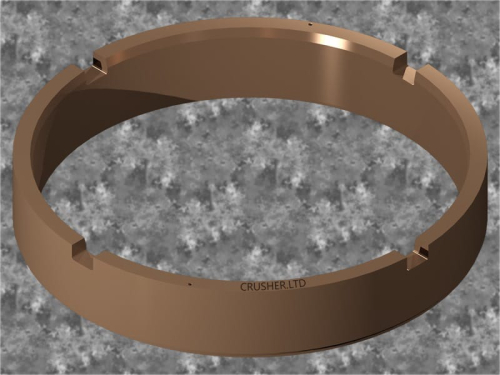

Crusher spare parts. Jaw and cheek plate lifting tools. Exclusively designed to lift Outotec manufactured wear parts for C jaw crushers.

Learn MoreJaw Plate Manufacturer - Bowl Liner | Blow Bar - Casteel Foundry

Our full-line of products from VSI Parts bucket Teeth ,hammers,blow bars To large Concave, Mantle , Jaw plates, Grates Mill Liners and much more have been highly recognized among customers and used in wide range of applications. 50MM CORRUGATED 504-015-083 J40 SWING JAW DIE GENERIC MODEL 504-003-022 C40 JAW DIE STANDARD PROFILE Mccolskey

Learn MoreWhat is the best material for crusher jaw plates?

23/12/ · There are some grades for manganese steel jaw plates: Mn14Cr2 Jaw Plates. Mn14cr2 jaw plates are used in crushing soft stone. For example, it has a good life when

Learn MoreThe Most Practical Jaw Crusher Repair and Maintenance Manual

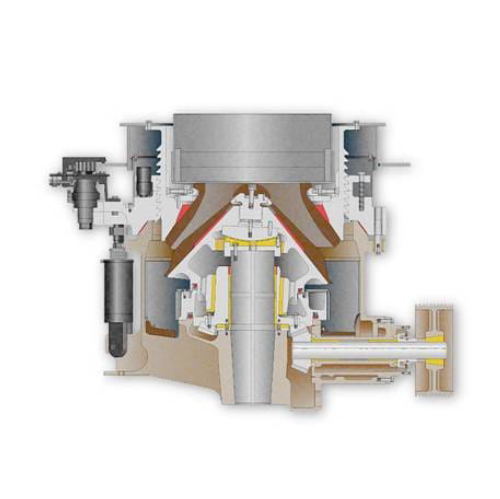

The function of toggle plate is to adjust the outlet of the jaw crusher to the desired size. There are two specific methods: one is to replace the support pad between the toggle plate and the body frame, and the other is to adjust the two wedges between the toggle and the body frame.

Learn MoreJaw Plate Manufacturer | Bowl Liner | Blow Bar - Casteel Foundry

Our full-line of products from VSI Parts bucket Teeth ,hammers,blow bars To large Concave, Mantle , Jaw plates, Grates Mill Liners and much more have been highly recognized among customers and used in wide range of applications. 50MM CORRUGATED 504-015-083 J40 SWING JAW DIE GENERIC MODEL 504-003-022 C40 JAW DIE STANDARD PROFILE Mccolskey

Learn MoreToggle Plate | Genuine Alternative Jaw Crusher Parts | GTEK

Toggle Plate is a simple & low-cost but very important part of jaw crusher. It is usually made of cast iron, and it is used to hold the lower part of the jaw in position, it also serves as a safety mechanism for the entire jaw. If something that the jaw crusher cannot crush gets into the crushing chamber accidentally and it cannot pass through

Learn MoreJaw Crusher Liner Plate Design & Profile Shapes

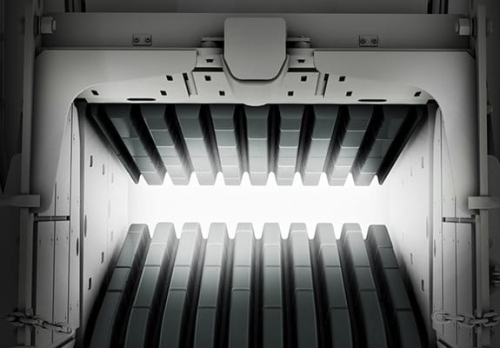

22/07/ · These non-choking jaw plates have been developed in two styles, reversible and non-reversible. The advantage of the reversible design has been outlined in connection with its

Learn MoreJaw Plates - SHANVIM

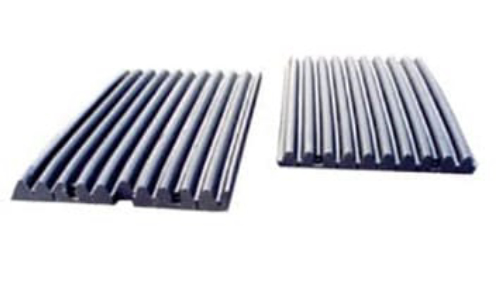

JAW CRUSHER PLATE-JAW LINER. Jaw Plates or Jaw Dies are the most frequently replaced wear parts of the jaw crusher, so the quality of the jaw die is one of the most important factors that determine the crushing efficiency and operating time. A set of jaw plates are composed of the movable (swing jaw) and fixed jaw plate (stationary jaw).

Learn MoreCrusher Jaw Plates For Popular Brands By Hunan JY Casting

Premium Crusher Jaw Plates. The crusher jaw plates are the main wear-resistant parts installed on the machine body to squeeze and crush the stone. Normally, it consists of a 1 piece fixed

Learn MorePioneer® Jaw Crushers - Astec

The Pioneer ® Series of jaw crushers represents the very latest in jaw crusher technology.. Engineered to be the highest-capacity jaw crusher on the market, the Pioneer ® Jaw Crusher will deliver up to 25 percent more tons per hour than comparable jaw crushers. Pair that with heavy-duty flywheels for reduced horsepower requirements and class-leading stroke for higher

Learn MoreWhat is a Jaw Crusher? – MEKA Crushing Equipment

The working principle of jaw crushers is based on the reciprocating movement of the movable jaw that compresses and crushes the rock or ore between itself and the fixed jaw, as the material enters the zone between the jaws. Toggle Plate 9. Swing Jaw 10. Discharge 11. Fixed Jaw. Jaw Crusher Parts. G: Gape width, b: maximum feed size,

Learn MoreJaw Plates | Crusher Mills, Cone Crusher, Jaw Crushers

To design an antifraying jaw plates of crusher should be used high quality metal in a jaw crusher machine. Jaw Plates, ShailAum Machine Manufacturers & Suppliers, India. Jaw Plates are one of the most important parts of jaw crusher. It is between two jaw plates (fixed and swing) that the crushing takes place. Since it's the part that

Learn MoreCrusher Jaw Plates Pattern - Hunan JY Casting

Crusher Jaw Plates Pattern Hunan JY Casting has thousand of crusher jaw plates pattern in our foundry, which will short your delivery time and save the pattern cost. Pattern types There are three types of patterns in our foundry: Foam pattern. The foam patterns are used to cast small (Weight less than 500 kg) jaw plates or trail orders;

Learn Morejaw crushers for all your needs - Lutze Process

Low jaw plate wear. • Large feed acceptance capability. These four factors are closely linked and the jaw crusher provides a good balance. The de-.

Learn MoreWhat happened? Jaw plates which need to change frequently for

26/11/ · The pivoted jaw swings around the pivot and makes an impact on the fixed jaw, crushing the fed lumps in the jaw crusher. In order to decrease the replacement cost, choose

Learn MoreResminer Stone Crusher Jaw Plates - Wear Resistance Supplier in China

The pattern of stone crusher jaw plate was used in this process to achieve the shape of the stone crusher jaw plate. Pouring Melted Chemical When the raw material turns into liquid, it will be transferred to the machine outlet to get the desired shape. Heat Treatment Process A modern and high-tech furnace machine is used in this procedure.

Learn MoreJaw plate and crusher liners For Shanghai Gator Machinery Crusher

Jaw Quarry Tooth Long 2022-02-22 Popular C Jaw Crusher Liners : Item Names: Jaw Plate s ,Stationary Jaw Tooth, Movable Jaw Die Fixed Jaw, Swing Jaw Plate , Jaw Fixed, Jaw Moveable , Cheek Plate , Side Plate,Jawface Fixed, Crusher Jaw Loose Casting Material: Austensti

Learn MoreHow to Choose the Right Jaw Plates for Jaw Crushers - Ware

05/11/ · The jaw crusher is a single toggle type of crushing equipment mainly used for variety of applications, including the medium to fine crushing process in the fields of mining, chemical industry, building materials, and refractories. As its name implies, this machine functions by using the “jaw plate,” which is derived from its wear-resistant

Learn MoreJaw Plates - Hysan Road & Bridge Mechanical Technology Co.,Ltd

Jaw Plates. Mantle,Concave,Jaw Plates are the mainly wear-resistant parts for cone crusher and jaw crusher. HYSAN is the professional supplier of high-chromium alloy cast iron, high manganese steel, super high manganese steel and other wear resistant Chromium alloy cast iron from 2008.Most of our products are made of Mn13Cr2 and Mn18Cr2 and are applicable to

Learn MoreCrusher Jaw Plate Latest Price, Manufacturers & Suppliers

Find here Jaw Plates, Crusher Jaw Plate manufacturers, suppliers & exporters in India. Get contact details & address of companies manufacturing and

Learn MoreChina Jaw Crusher Accessory Deflector Plate, Jaw Crusher

China Jaw Crusher Accessory Deflector Plate manufacturers - Select 2022 high quality Jaw Crusher Accessory Deflector Plate products in best price from certified Chinese Accessory Equipment, Metal Accessory suppliers, wholesalers and factory on

Learn MoreWhat happened? Jaw plates which need to change frequently for jaw crusher!

Our replacement jaw feature in three grades depending on the crushing conditions encountered 13%MN, 18%MN, 21%MN. BDI's replacement jaws offer to wear life and fit and go through a rigorous quality control process. Benefit: Proprietary alloys offer increased toughness and durability. Better fit for quick and easy replacement

Learn MoreHow to Choose the Right Jaw Plates for Jaw Crushers

05/11/ · The jaw crusher is a single toggle type of crushing equipment mainly used for variety of applications, including the medium to fine crushing process in the fields of mining,

Learn MoreC160 Crusher Jaw Plates - Hunan JY Casting

Aftermarket C80 Crusher Jaw Plates By Hunan JY Casting When it comes to C160 crusher jaw plates, Hunan JY Casting focuses on manufacturing those wear parts for a long time. Although we are not the OEM foundry, our aftermarket C160 crusher jaw plates can 100% match the original sizes based on the customer's drawings or sample parts.

Learn MoreJaw Crusher Plates - Wear Parts For Industry | Qiming Casting

Our foundry had succeeded to offer jaw plates for crusher, crusher and other famous brands.On the other hand, Qiming Casting also offer a variety of manganese contents, from 14% up to 22% for the more demanding applications. In some means, we also improve material choice and casting technology. Wedges Wedges

Learn MoreJaw Crusher Wear Parts - Unicast Inc

Increase machine up-time with Unicast Jaw Crusher replacement wear parts including jaw plates, cheek plates, wedges, and toggles.

Learn MoreJaw Crusher Plates - Wear Parts For Industry | Qiming

Liner Plate And Cheek Plate. Qiming Casting offer the complete range of liner plates and cheek plates for all kinds of brands jaw crushers range.The liner plates have an important role to play

Learn MoreHow does a Single Toggle Jaw Crusher work? - Rubble Master

The two jaw plates are positioned in a V-shape so that the space narrows from top to bottom. The angle within the V is known as the nip angle. An elliptical

Learn MoreJaw Plate, Teeth Plates, Jaw Crusher Wear Parts for Sale - Willing

Jaw Plate is the main wear part of Jaw Crusher, including fixed plate and jaw plate . We can produce a variety of meet the requirements of the jaw plate according to the customer's model .

Learn MoreJaw Plates Latest Price from Manufacturers, Suppliers

Approx. weight : 7500 Kgs. Inches : 24"x12". Jaw Crusher from are used to reduce the blasted

Learn MoreJaw Crusher | Crushing Plant | Hard Rock Mining Equipment | DOVE

The two Jaw Plates are the main working part inside the crusher. One Jaw plate (Fixed plate) is positioned vertical and fixed on the front part wall inside the crushing chamber, the other Jaw Plate (Movable Jaw Plate) is in inclined position opposite the Fixed Jaw Plate. The electric motor drives the Belt and Pulley to make the Movable Jaw

Learn More

Leave A Reply