Types of Crushers: What You Need to Know - Machinery Partner

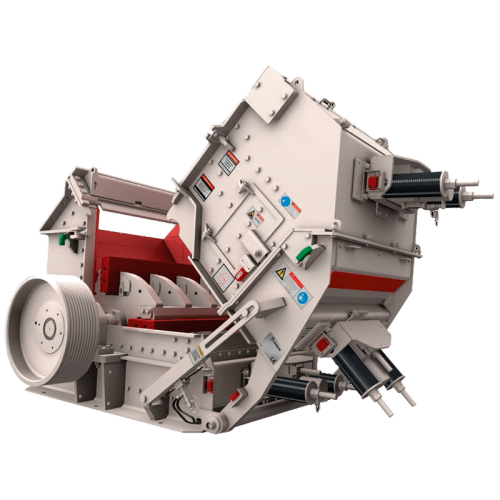

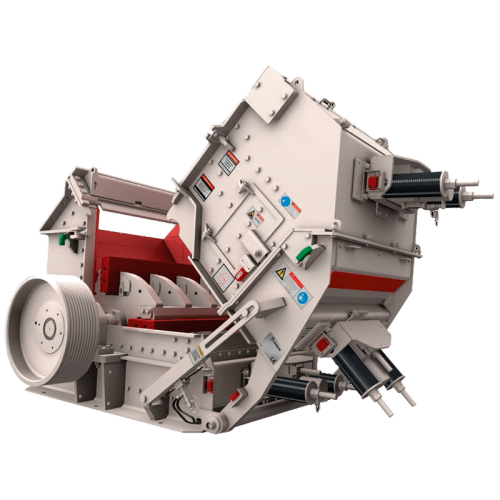

Primary crushing produces materials ranging from 1500mm to 350mm, on average. The two main types of primary crushers are: Jaw Crushers: large amounts of material are fed into the “V

Learn MoreWhat Are the Differences Between The 7 Types of Crushers?

2022/7/20 · A high-quality hammer crusher can keep final material 100% passing a twenty mesh, fifty to sixty percent passing a fifty-mesh screen. Crusher hammers are high chrome content. The hammer service life depends on the material you process. If you're running abrasive quartz, they'll last somewhere between one to two weeks.

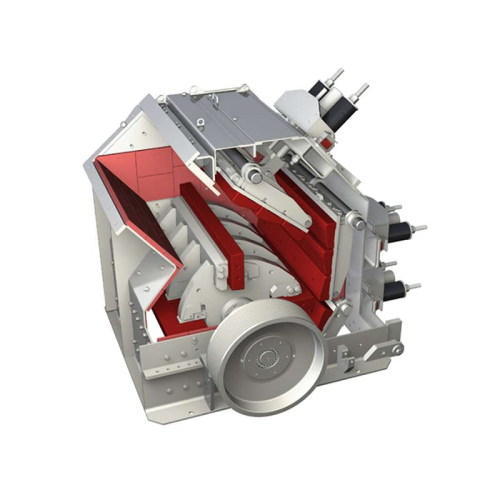

Learn MoreWhat Is Impact Crusher|Working Principle, Parts And Types

Impact crusher working principle. When the stone falls into the working area of the blow bar (hammer), it is crushed by the impact of the blow b the high-speed rotating rotor, and is thrown to the apron for a second impact, and rebounds until the rotating blow bar (hammer) is hit again. This process is repeated until the material is

Learn MoreSo How Exactly Does a Rock Crusher Work? - Geology

9/22 · A rock crusher is a device used to crush rocks into smaller pieces, usually for gravel or some other road or building application. Most rock crushers have a hopper at the top — a container which holds the rock above the crusher and uses gravity to feed it in. Alternately, rock crushers can use a belt drive to .

Learn MoreWhat is a crusher tee shirt?

Lifes Good • What is a crusher tee shirt?-----Our mission is informing people properly. With this video, our main goal is to spread scientific knowledge

Learn MoreLake Erie Crushers

The Lake Erie Crushers and the majority of the Frontier League entered Sunday night with one final game to play. Although there wasn't much for the Crushers to play for, Lake Erie was looking to avoid the seep against

Learn MoreEverything You Need to Know About Rock Crushers

Compression-style jaw, cone, impact crushers, and gyratory crushers are most often appropriate as primary crushing equipment types, though there can be overlap

Learn MoreStone crusher Definition & Meaning - Merriam-Webster

The meaning of STONE CRUSHER is a machine for crushing stone.

Learn MoreBuyer's Guide: Crushers - Equipment & Contracting

Jaw Crusher. A jaw crusher is the most commonly used primary crusher. · Impact Crushers. An impact crusher (also called a hammer crusher) is quite versatile.

Learn MoreCrush Definition & Meaning

OTHER WORDS FROM crush ; crush·a·ble, adjective ; crush·a·bil·i·ty, noun ; crush·a·bly, adverb ; crusher, noun.

Learn MoreWhat Is a Cone Crusher and What Can It Do for You?

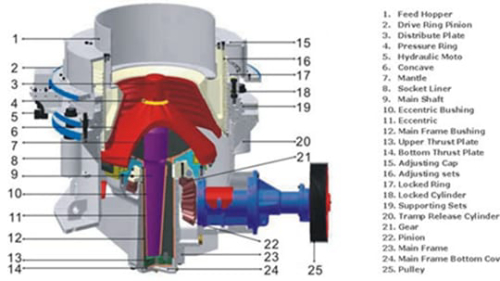

Apr 24, A cone crusher is one of many different types of crushers, like impact crushers, jaw crushers, and hammermills, that is used to process and reduce material like aggregates and construction and demolition waste. The cone crusher distinguishes itself from these other crushers by how it operates in processing material.

Learn MoreChemical Processing 101: Crushing - Howard Industries, Inc

Industrial crushers are primarily used to take very large pieces of material and make them smaller. Having smaller pieces of the material

Learn MoreWhat is a - Compactors Inc

1/14 · Can Crushers are used for crushing empty, full, half-full, line rejects, or off date products aluminum or steel cans for easier recycling. A can save you a significant amount of time and space. Using a to reduce the capacity of waste materials means cutting the expense of waste transport.

Learn MoreWhat is a Crusher? (with picture) - About Mechanics

A crusher is a device that's used to decrease the size of objects by using force to reduce them into a smaller and more compact

Learn MoreHow Does a Rock Crusher Work? - Sciencing

A rock crusher is a device used to crush rocks into smaller pieces, usually for gravel or some other road or building application.

Learn MoreWhat a Is and How it works

10/27 · is a tool that is used for crushing empty aluminum cans for easier recycling. It is a tool for everyday usage and is especially useful for those, who use a lot of cans, for example, drinking soda from aluminum cans. The most common type of cans that people use regularly are soda cans. If you are a common soda drinker, you probably

Learn MoreCrusher - an overview | ScienceDirect Topics

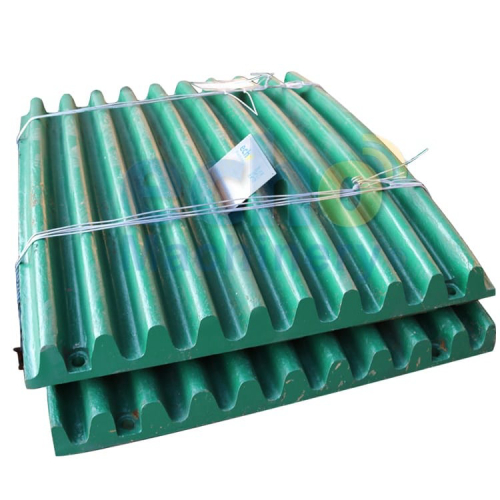

Crusher. The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation. From: Mineral

Learn MoreWhat is jaw crusher used for? - Sandrock Mining

3/29 · The jaw crusher can be used for the processing of granite, marble, basalt, limestone, quartz stone, river pebble, iron ore, copper ore, and other materials. Generally used for primary crushing, it is the first-choice equipment for various crushing production lines.

Learn More10 Best Pill Crushers September 2022 - MSN

9. 4 Pack Pill Crusher Pulverizer Grinder with Storage Container, 2 x 3.25 inch. By juvale. 7.4. View Product. 7.4. 10. Medline Silent Knight Pill Crusher Pouches (Pack of 1000) By biotene.

Learn MoreUnderstanding the Different Types of Crushers | Agg-Net

Cone crushers and gyratory crushers are also compression-type machines that crush material between a moving piece of steel and a stationary piece. The output is

Learn MoreWhat is a Jaw Crusher? - MEKA Crushing Equipment

We call this process SIZE REDUCTION or CRUSHING. The goals of the size reduction are as follows: 1.) Obtaining the size or surface area required for the use of the ore or material 2.) Allowing ease of transportation and storage 3.) Separating the different minerals contained within the ore and to release them from one another 4.)

Learn MoreWhat does Crusher mean?

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, or rock dust. Crushers may be used to reduce the size, or change the form,

Learn MoreAll crusher types for your reduction needs - Outotec

The main purpose of a primary crusher is to reduce the material to a size that allows its transportation on a conveyor belt. In most crushing installations a jaw crusher takes care of primary crushing. Plants with very high capacities that are common in mining and less popular in aggregates production, normally use a primary gyratory crusher.

Learn MoreTypes of Rock Crushers | Quarry Crushing Equipment | Kemper

As foundational material handling equipment in all plants, crushers need to coordinate seamlessly with screens, conveyor systems, and washing equipment. Today we're breaking down everything you need to know about crushers to help you understand the questions you should ask as you search for the right material handling equipment for your operations.

Learn MoreCrusher - The Cycle: Frontier Wiki

2022/8/25 · Heavy rock throw: the crusher forms a rock from the ground using the two grabbers on its back. This attack takes longer to charge, but does higher damage than the light rock throw. The Crusher's weak spot is located on its back beneath its grabbers. If the orange ankles of the Crusher take enough damage, it will cancel whatever attack its

Learn MoreWhat Is a Jaw Crusher and What Can It Do for You?

11/8 · A jaw crusher is one of several types of crushers, including impactors, hammermills, and cone crushers, that are manufactured for the purpose of processing aggregate minerals, RAP, and recycled concrete with rebar, to name a few applications. There are two types of crushing, compression or impact. Jaw crushers and cone crushers use a compression force

Learn MoreA Detailed Overview of Cone Crushers and What You Need to Know

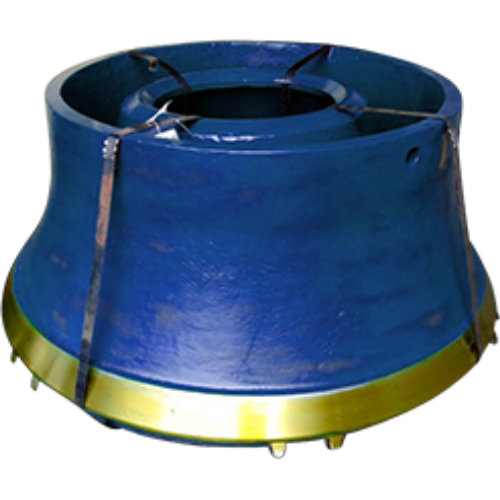

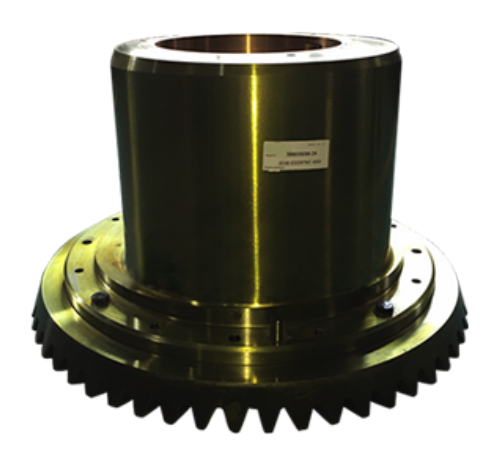

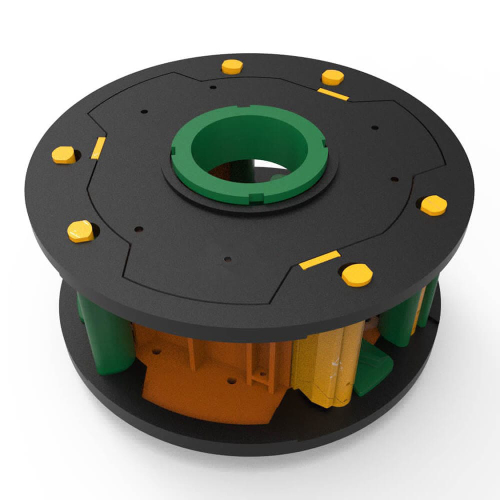

6/3 · Cone crushers are compression machines that take in raw materials and reduce them in size by crushing them. A variety of industries rely on these tools, such as the concrete, aggregate, mining, coal, and natural gas industries. Inside the crusher, a piece of steel, known as the mantle, rotates eccentrically.

Learn MoreCrusher drone by MarModels - Thingiverse

Download files and build them with your 3D printer, laser cutter, or CNC. Thingiverse is a universe of things.

Learn MoreCrusher Run - What is it? - Gravelshop

The material is most commonly used in home projects as a compactible sub-base material. It is a combination of coarse and fine aggregates that form a solid, level base of support for the top layers of things like driveways, patios, and structural foundations. Crusher Run Prices Shop Crusher Run What is Crusher Run made out of?

Learn MoreCone Crushers | McLanahan

A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steel. Final sizing and reduction is determined by the closed side setting or the gap between the two crushing members at the lowest point. As the wedge or eccentric rotates to cause the compression within the chamber, the

Learn More

Leave A Reply