What is a Jaw Crusher? - MEKA Crushing Equipment

This angle depends on the size, hardness and frangibility of the material. It cannot be selected as too large or too small. The nip angle in primary crushers is lower than in secondary crushers. Generally, this value is between 18 and 24 degrees in primary jaw crushers, and between 22 and 28 degrees in secondary crushers.

Learn MoreCrushers - All crusher types for your reduction needs - Outotec

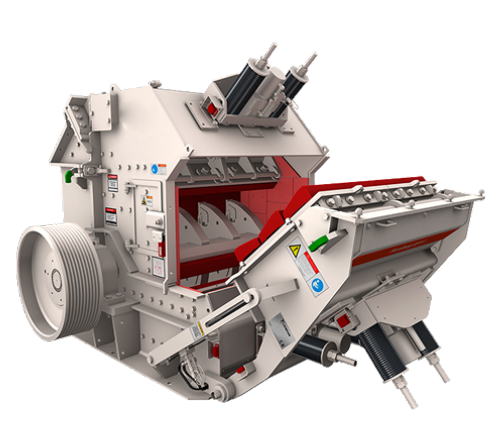

The primary impact crushers are used to process from 200 t/h up to 1900 t/h and feed sizes of up to 1830 mm (71") in the largest model. Primary impact crushers are generally used in nonabrasive applications and where the production of fines is not a problem. Of all primary crushers, the impactor is the crusher that gives the best cubical product.

Learn MoreCrushing and Screening Handbook - AusIMM

duction rate and the size and shape of the fin- ished product. closed circuit screening, final sizing and de- watering. Size of primary crusher.

Learn MoreDifferent Types Of Crushers Machine Of Primary,secondary And Tertiary

Stone crushing plant,Primary crusher,Secondary crusher,Tertiary of primary, secondary and tertiary crushers, machine lilimingne feeding size 10mm; types of Several types of coal crushers - Stone Crusher Machine/Gravel Several types of coal crushers: in primary or secondary crushing process.

Learn MoreSuperior™ MKIII Series primary gyratory crushers - Outotec

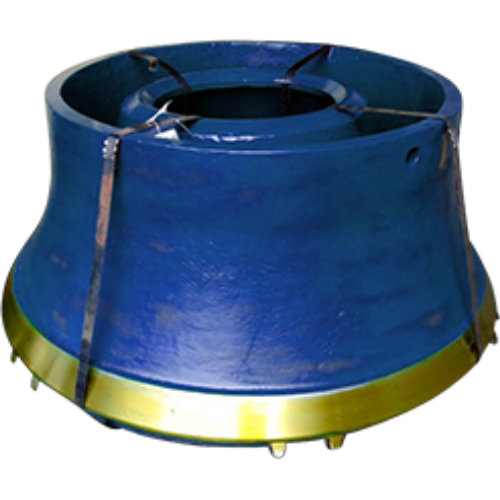

Superior™ MKIII primary gyratory crushers have new sets of shells and concaves, which have been implemented after countless hours of research and development. The improvements to the Outotec Outotec Superior™ MKIII crushers brings up to 70% reduction in downtime. Crusher maintenance downtime has also produced a significant size

Learn MoreHPI-H | PRIMARY IMPACTOR | Hazemag North America

HPI-H Primary Impactor. The HPI-H Primary Impact Crusher is ideally suited for crushing medium-hard rock down to a well graded product size of 0 – 6 inch. Due to its operational flexibility, economical operation and excellent product size control, this machine is widely accepted as the machine of choice for the North American Aggregate Industry.

Learn MoreCrushing in Mineral Processing

12/26 · Producing such a fine crush generally requires multiple crushing stations of up to 4 being but as a minimum of 2 being oversized. The gape determines the maximum size of material that can be accepted. Primary crushers are designed so that the maximum size that can be presented to the crusher is approximately 80% of the gape.

Learn More1 Crushing - Springer

Source: Courtesy of the Fuller. Company. jaw crusher. However, with the over-capacity of both jaw and gyratory crushers, especially in the larger crusher sizes,

Learn MoreDifferent types of crushing equipments - Constro Facilitator

5/6 · Types of crusher depend on the feeding method. These are- Primary crusher, Secondary crusher and Tertiary crusher. The primary crusher is only for the breaking of large stones into pieces (this means primary crusher is not for the aggregate size material.). Examples of primary crushers are jaw crusher; hammer mill crusher and gyratory crusher.

Learn MoreWeight Of Primary Crusher | Crusher Mills, Cone Crusher, Jaw Crushers

The Jaw crusher is used for Primary crushers and Secondary crushers for crushing all kinds of minerals and rocks Total weight (t) Dimensions (L*W*H) (mm) PE-150*250. 150 Primary Impact Crusher – – Crushing, Grinding Primary Impact Crusher. PFP impact crushers are generally used as a primary crushers for crushing quarry rock,

Learn MoreThe Importance of Primary Crushing in Mill Feed Size

I-197 At this time, Highland Valley does not blend its ore sources based on fragmentation size (although it is possible). Therefore, the other blending constraints (grade, hardness, etc.) dictate the crusher feed blend which can mean large variations in fragment size

Learn MoreDifferent Types Of Crushers Machine Of Primary,secondary And Tertiary Crushers | Crusher Mills, Cone Crusher, Jaw Crushers

Secondary; 3)Tertiary; A primary crusher receives the our crushers are divided into three types: Gold ore crusher machine size is different, primary and secondary crushing reports – CGM Mine Machine Mine Machine Plant. include primary

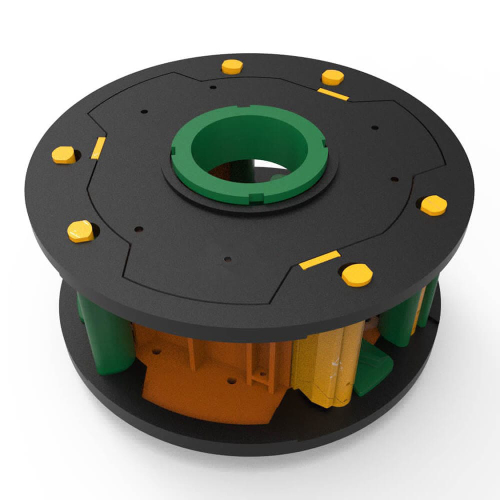

Learn MorePrimary Sizer Crusher - Henan Excellent Machinery Co., Ltd

Primary breaking (ring teeth) Classification type tooth primary sizer crusher feeding particle size ≤1200mm, discharging particle size ≤300mm, 250mm, 200mm, etc., can crush coal rock and medium strength rock such as coal, salt, gypsum, phosphate, limestone, bauxite, petroleum coke, lignite, Trona, carbon anodes, oil sands, clay, shale, etc.

Learn Moreprimary crusher product

The product specification is complete the feed size from 80 850 mm PE type jaw crusher crushing materials of compressive strength of up to 300Mpa is a complete

Learn MoreCrushers - an overview | ScienceDirect Topics

Primary coal crusher: Used for larger coal size. The primary coal crushers may be of different types such as: (1) coal jaw, (2) coal hammer, and (3) ring granulator. Secondary coal crusher: Used when the coal coming from the supplier is large enough to be handled by a single crusher. The primary crusher converts the feed size to one that is

Learn Moreprimary and secondary crusher | bushing of ball mills picture

Primary crushing. As the first stage in a crushing circuit, primary crushing reduces material to a size and shape that can be handled by a secondary crusher. Typically, the minimum setting on most primary crushers is about 4 in. to 6 in. Jaw, gyratory and impact crushers are most often appropriate as primary crushers, although there can be

Learn MorePDF) SIZE REDUCTION BY CRUSHING METHODS - ResearchGate

3/4 · There are two major categories of processing. One is comminution and the other one is separation. The process "Comminution" involves size reduction and size-wise classification called as screening

Learn Moresize of primary crusher

crushing products size and shape -what to expect. Feb 26, · The difference between the cumulative percentages at the 3.5″ and 1.5″ points on the curve gives us the amount, of such product to be expected from the output of the primary crusher This is 85 minus 43, or 42% of the primary crusher product.

Learn MorePrimary Crusher | Crusher Mills, Cone Crusher, Jaw Crushers

Jaw crusher,Jaw breaker,Jaw crushers,Stone crusher,Rock . It is mainly applied in the primary crushing in which the compressive strength of original material is under 320Mpa. Jaw

Learn MoreHigh-Efficiency Cone Crusher ZI Cone Crusher | ANSWERS

Aggregate quarries and mining operations use several types of crushers, with primary

Learn MoreChoosing the Right Primary Crusher for Your Aggregates Application

One should start with the purpose of the crusher, move to model refinement and finish with a successful installation. The primary crusher is a workhorse that converts the blast feed size to a smaller size to manage for the other site components (belts, screens, and eventually any secondary crushers) on the path to the finished product.

Learn MorePrimary Crushers Market Size 2022, projected revenue ... - MarketWatch

The Primary Crushers Market report also indicates a point-wise outline of market share, market size, industry partakers, and regional landscape along with statistics, diagrams, & charts

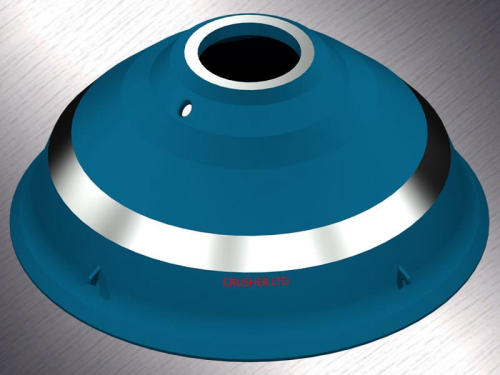

Learn MoreGyratory Crusher | Hazemag North America

A gyratory crusher is one of the main types of primary crushers in a mine or ore processing plant. Gyratory crushers are designated in size either by the

Learn MoreSteele Primary Crushers - Steele Machinery - J.C. Steele & Sons

Maximum size of 36" across any dimension 10-12" average dimension Output particle size less than 1" to less than 4," depending on roll spacing Throughput 60-200 tons per hour at 1" roll setting Industry Applications Primary crusher for clay working applications—brick, block and tile Industrial minerals Primary Crusher auto grease system.

Learn MorePDF TECHNICAL NOTES 5 CRUSHERS - Mineral TechPDF

Figure 5.1 Schematic diagram of a crusher showingg the open- and closed-side settings. 5.1 Jaw and Gyratory Crushers. Jaw and gyratory crushers are used mostly for primary crushing. They are characterized by wide gape and narrow discharge and are designed to handle large quantities of material. The capacity of the crusher is determined by its size.

Learn Moreprimary crushers sizer

Primary Crusher Average Size Stones - . Deze pagina vertalen. Primary crusher average size stoneshe earliest crushers were hand-held stones, where the weight of the stone provided a typical processing line at a mine might consist of a crusher followed by a primary crushing reduces the large pieces to a size which can be handled by contact supplier small scale mechanized stone crusher, get

Learn MoreWhat is Primary, Secondary and Tertiary Crushing? - Polygonmach

2022/4/21 · Primary crushing is the first step in crushing the material and can sometimes be sufficient to achieve the desired product size. The primary crusher takes oversized material to be blasted, excavated or recovered to be sent to the crusher and processes it via a crusher, jaw or rotary crusher to create various product sizes. For many aggregate

Learn MoreAMIT 135: Lesson 5 Crushing - Mining Mill Operator Training

Primary Crushing · The purpose of the primary crusher is to reduce the ROM ore to a size amenable for feeding the secondary crusher or the SAG mill grinding

Learn MorePDF Handbook of Crushing - TerraSource GlobalPDF

crusher. Primary Crusher — The first crusher in a crushing system into which material is fed. Succeeding crushers in the system are referred to as secondary or tertiary crushers. Product — Output from the crusher. Reduction Ratio — The ratio of the top size of input material to the top size of crusher discharge.

Learn MoreCrushers and Their Types - IspatGuru

The output of the primary crusher is fed to a secondary crusher, which further reduces the size of the material. Similarly the output of

Learn MoreSize distribution and production rate of crushed rock by jaw

example, if it is fed 500 TPH of blasted rock to a jaw crusher which has CSS (a) Open circuit (b) Close circuit at 2

Learn More

Leave A Reply