Cone Crusher For Sale - Secondary Crushing Equipment

Spring cone crusher is suitable for materials: pebble, limestone, dolomite, granite, rhyolite, diabase, basalt, ferrous metals, etc. 1. Spring cone crusher is a kind of stone cone crusher widely used at present, because of its reliable operation and good performance, it is widely used in mines and gravel fields around the world. 2.

Learn MoreCone Crushers | Mobile & High Productivity | Finlay

Cone Crushers. Finlay® Cone Crushers are renown for their capabilities in crushing mid-hard and above mid-hard ores and rocks. The Finlay range of cone crushers provide flexibility, high rates of productivity and excellent product shape in secondary and tertiary applications.

Learn MoreCrushing and Screening Handbook - AusIMM

contributes to an improved understanding of quarrying operations and thus Jaw, cone, gyratory, and roller crushers operate.

Learn MoreMaximising cone crusher efficiency | World Highways

30/09/ · Ensuring efficient cone crusher operation can deliver major economies of scale for quarrying facilities There are a number of ways in which cone crusher throughput can be optimised. One of the key issues is in keeping the system choke fed during operation, as this maximises the effectiveness of rock-on-rock crushing, extends the wear life of manganese

Learn MoreTrio® TC Series Cone Crushers - The Weir Group

This design has been proven to perform in heavy-duty secondary and tertiary crushing applications being tough, reliable, simple to operate and easy to maintain.

Learn MoreCone Crusher Operation | Crusher Mills, Cone Crusher, Jaw Crushers

Cone Crusher Maintenance,Cone Crusher Operation,Cone Crusher A. the materials must be in the middle of the distributor, see diagram 14. it is not allowed to put the materials into the

Learn MorePDF Crushing Plant--Hydraulic Cone CrusherPDF

The JOYAL Hydraulic Cone Crusher is widely used for secondary and fine crushing in the fields of mining, building materials, metallurgies and so on. The hydraulic cone crusher can crush materials with middle and high hardness such as, ironstone, copper ore, granite, basalt, cobblestone, marble, limestone and so on.

Learn MoreHP4™ cone crusher - Outotec

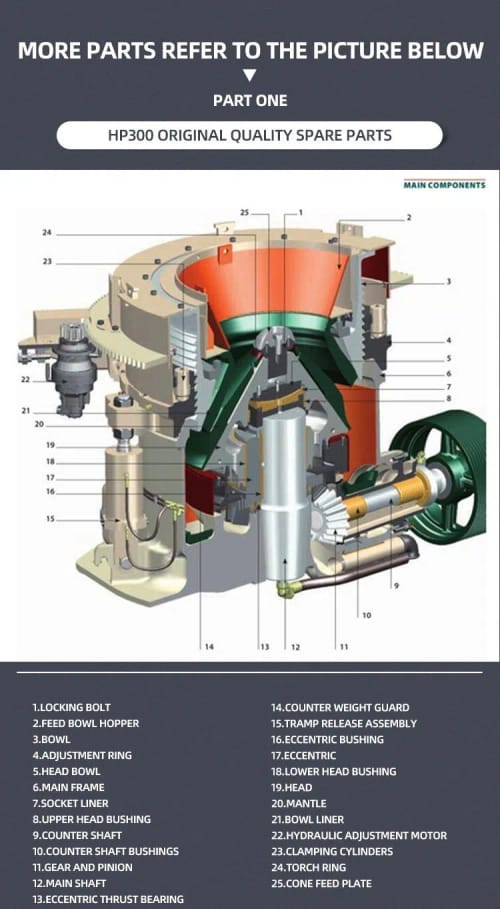

HP4™ cone crusher is one of the latest models in the new generation of ® HP Series™ cone crushers family. It has proven to be productive in both aggregates production and mining operations. This cone crusher is often utilized in the second, third or fourth stage of the crushing process.

Learn MoreOperation Manual For Cone Crusher

ElJay Rollercone Classic Owner/Operator Manual. This book is an operation manual for the new owner/ operator of a Rollercone Crusher . Standard Head Cone Crushers.. 3.3 Anti-Spin

Learn MoreFULLTEXT01.pdf - DiVA portal

crushing circuits and its leading equipment, the cone crusher, in either industry. Operating variables of cone crushers.

Learn MoreCone Crushers | Moore Watson Ltd

MHP Cone Crusher Easier Adjustment.jpg. Tramp release and Hydraulic settings. Easier Operation. MHP series is fitted with a forged high tensile main shaft

Learn MoreCone Crusher Operation Model | Crusher Mills, Cone Crusher, Jaw Crushers

The cone crusher, which is crushing ores and rocks of medium hardness above, is used of big crushing force, high efficiency, large handling capacity, low-cost operation CS Cone Ore Crusher - ore crusher,ore grinder - Machinery

Learn MoreCone Crushers | Crushing Plants | DOVE

Field Adjustments. Cone Crushers are configured with Hydraulic Lifting-Arm, where in the case of power failure, it allows the operator for rapidly rotating and removing the top-shell in order to remove the stuffed material inside the crushing chamber. The hydraulic adjustment unit will also allow easily and rapidly to perform the required setting adjustments, and changeovers of

Learn MoreCone crusher animation – MX Multi-Action

21/03/ · The MX™ cone crusher is based on the patented Multi-Action crushing technology, which combines the piston and rotating bowl into a single crusher. The

Learn MoreCone Crushers | McLanahan

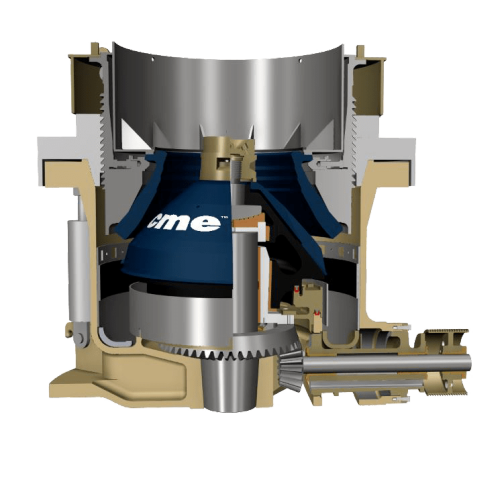

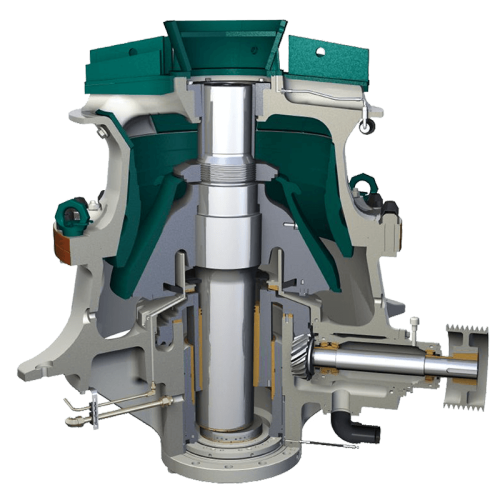

A Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steel.

Learn MoreSpring cone crusher, Hydraulic cone crusher - Crushing Plant

A cone crusher is similar in operation to a gyratory crusher, with less steepness in the crushing chamber and more of a parallel zone between crushing zones

Learn MoreCone Crusher Operation - China Manufacturers, Suppliers, Factory

Getting started; Cone Crusher Operation; Cone Crusher Operation - China Manufacturers, Suppliers, Factory. We offer fantastic energy in high quality and enhancement,merchandising,profits and promoting and procedure for Cone Crusher Operation, Hti 1010 Liners, C100 Jaw Plate, 10 X 16 Jaw Crusher For Sale,Mn13cr2 Swing Jaw.We sincerely welcome overseas customers to consult for the long-term

Learn MoreEfficient use of cone crushers - Mineral Processing

A cone crusher is often used in the second to third crushing stage and operates according to the pressure crushing principle. It is suitable primarily for

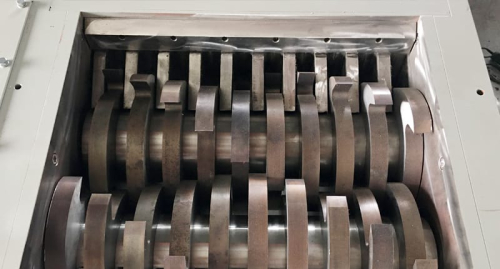

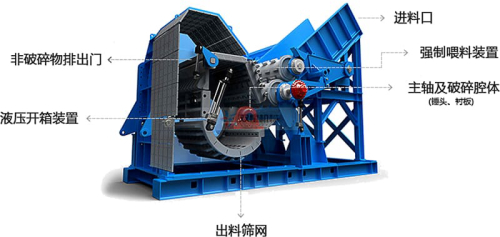

Learn MoreThe Differences Between Cone Crusher and Impact Crusher

Cone crusher and impact crusher are both secondary fine crushing equipment, and their differences are described as follows:. 1. The different working principle: Cone crusher adopts the principle of lamination crushing. During operation, the particles and the lining plate, the particles and the particles are kneaded with each other, so that the flat and long particles are broken

Learn MoreCrushing Plant--Hydraulic Cone Crusher

The JOYAL Hydraulic Cone Crusher is widely used for secondary and fine crushing in the fields of mining, building materials, metallurgies and so on. The hydraulic cone crusher can crush materials with middle and high >> advanced crushing principle and technical data, reliable operation and low operation cost. All parts of the crusher have

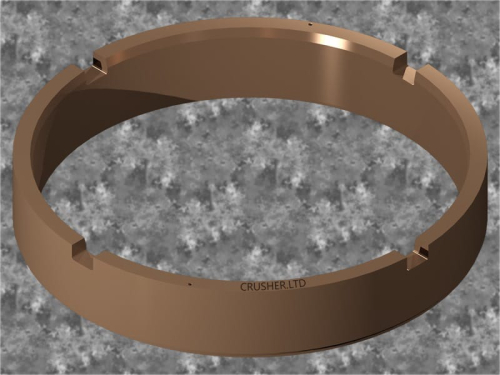

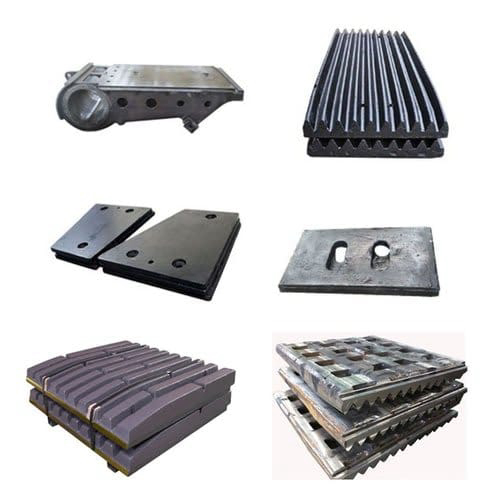

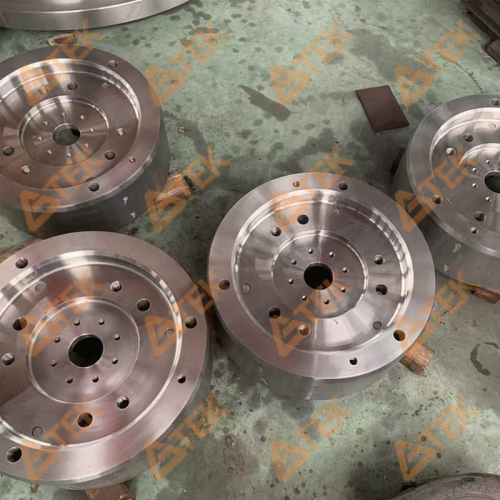

Learn MoreCone crusher parts - Outotec

Our cone crusher parts are designed to the same specifications and standards as our cone crusher equipment, ensuring equipment compatibility for reliable and safe operation. Carefully produced at our own foundries We have complete control over quality at every step of the process, from the selection of raw materials to final production.

Learn Morespareparts of gp11f cone crusher hs code (2022

Stone Cone Crusher Wear Plate Suit for T300 Spare. Stone Cone Crusher Wear Plate Suit for T300 Spare Parts, Find Details about Stone Cone Crusher, Crusher Wear Plate from Stone Cone Crusher Wear Plate Suit for T300 Spare Parts - Maanshan City Hyton Heavy Industry Technology Development Co., Ltd. HS Code: 84749000.

Learn MoreMobile Cone Crusher Plants - Screen Machine

The CST Cone Crusher is a medium-to-large size, track-mounted crusher plant designed for secondary crushing of hard rock into cubical sizes. Featuring a heavy-built "quarry duty" cone crusher, the CST is perfect for rock quarries and other mining operations. View CST Mobile Cone Crusher CXT Mobile Cone Crusher

Learn MoreCalibration and Validation of a Cone Crusher Model ... - MDPI

operation; no additional laboratory tests are required. K1 to K3 and the cone crusher operating parameters are given by:.

Learn MoreMaximize your cone crusher productivity - Pit & Quarry

1. Operate at a consistent closed-side discharge setting. · 2. Operate at a consistent “choke-fed” cavity level. · 3. Do not trickle feed the

Learn MoreJaw and Cone Crusher Myths & Total Operating Costs

Replacing a Jaw & Cone Crusher Setup by a Mobile Impact Crusher Improves Material Quality & Total Operating Costs. Impact crushers can be used in many rock

Learn MorePragmatic Approach for Cone Crusher Operation Follow-up

PDF | Cone crushers are very well implemented in the aggregates industries. They are used in secondary and tertiary applications where the

Learn MoreHP Series™ cone crushers - Outotec

Crusher automation. Outotec IC70C™ is a crusher automation system that further improves the operation of your ® HP™ crusher. Using it can increase your production by more than 10%. With Outotec IC70C™ you can control maintenance, setting modifications, production follow-up and data extraction.

Learn More12 tips to maximize cone crusher productivity - Outotec

A crusher should be operated above 40% but below 100% rated horsepower in order to maximize cone crusher productivity and to have a proper “

Learn MoreCone Crusher | Working Principle | Animation - Engineering Intro

Cone crusher and gyratory crusher work on the same principle. Both have the same operation. If cone crusher differs then it is only from

Learn MoreCaring for your cone crusher: A guide to optimising performance

A cone crusher punishes itself in every minute of operation. It squeezes a dense mass between heavy castings until the mass disintegrates.

Learn More

Leave A Reply